Meet the Experts: The Use of MES in Complex Assembly

Not even the global health crisis managed to slow down the growth of the manufacturing execution systems (MES) market, which is predicted to reach USD 24,344.35 Million by 2025 as reported by Valuates Reports.

The need for manufacturers to keep up with the growing population and supply chain demands calls for a unified solution that’ll allow seamless real-time data collection and monitoring of manufacturing activities across the entire process – thus, the inevitable rise of manufacturing execution systems.

Complex manufacturing is no different in that aspect. We have noticed an increased interest regarding the use of MES in complex assembly and as a result, we put together one of our “Meet the ExpertS” webinar to address some of your most frequently asked questions. First, let’s expand on the concept of complex production.

What is Complex Manufacturing

Complex Manufacturing is a serialized, slow-moving production characterized by an extended product cycle time and manual labor. Where in batch production manufacturing companies are required to track products by day/batch/lot, complex manufacturing demands for each serialized product unit to be tracked individually.

We recognize three primary production strategies in Complex Manufacturing:

Make to Stock (MTS), where large quantities of the end-product are manufactured based on the anticipated consumer demand. MTS commodities are often stored as inventories until purchased and then shipped to the end-user. You’re most likely to find MTS being used in the automotive and medical devices industries.

Make to Order (MTO), where manufacturing of the end-product only begins when a customer places an order for it. This type of production extends wait time but allows greater flexibility and product customization. You’re most likely to find MTO being used in the aircraft manufacturing industry.

Engineering to Order (ETO), where the end-product is built from scratch based entirely upon customer’s requirements. It’s a highly complex production process that demands close collaboration between engineers (manufacturing company) and the customer. You’re most likely to find ETO being used in the shipbuilding and space industries.

As you can imagine, together with their process flows, the characteristics of Complex Manufacturing pose many challenges for the manufacturers, including:

● Long cycle time and low volume serialized production driven by a one-piece flow

● Complex process routing, rework and engineering changes

● Complex and multilevel BOM’s (Bills Of Material)

● Work Instructions compliance

● Production data traceability for future analysis and legal regulations

● Highly skilled operators

● Security and quality regulations for military and medical areas

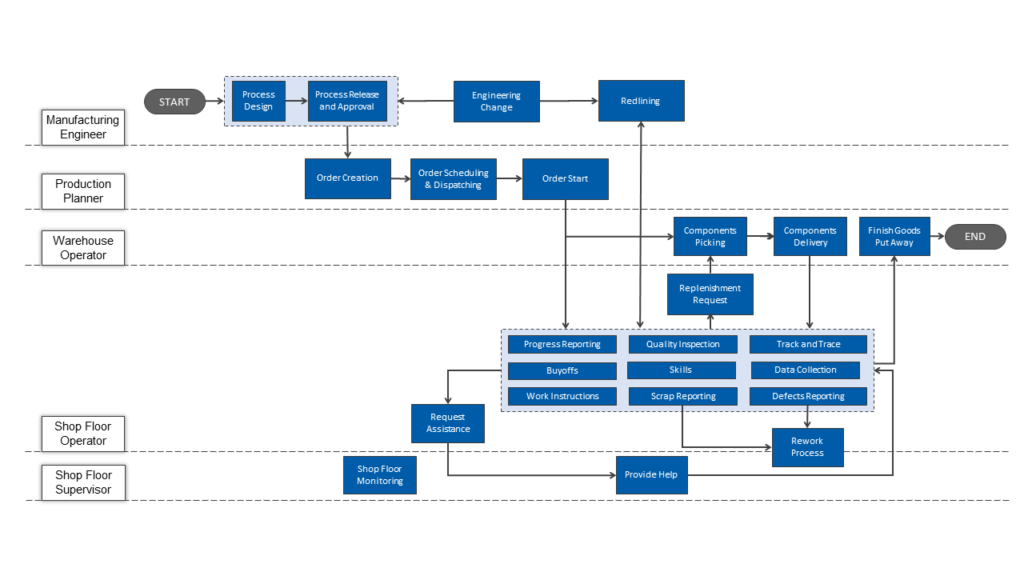

Below, you’ll find an example of a typical process flow to give you a clearer understanding of what a standard complex assembly process looks like.

We have received multiple questions regarding the application of manufacturing execution systems in complex manufacturing therefore we decided to address those in the “MES in Complex Assembly” webinar as well as in the Andea Guide document available for download below.

In both, you’ll find answers to the following questions:

How do you typically handle changes to the production orders and associated work instructions once a production order has been started in Apriso?

What are some of the hidden challenges that you have experienced that were surprisingly difficult when deploying MES in a complex assembly environment?

How do you handle ‘First Article’ parts in production?

In your experience – what was the most challenging project you have done and why? What were the major lessons you learned along the way?

How do you handle linking an MES up to an Advanced Planning and Scheduling system?

How do you handle complex BOMs with changing engineering requirements and designs?

You also might like

Pioneering the Path Forward: Unpacking the CoorsTek Factory Showcase

Pioneering the Path Forward: Unpacking the CoorsTek Factory Showcase The recently culminated CoorsTek Factory Showcase, in collaboration with Dassault Systèmes and hosted at CoorsTek Factory,

CoorsTek Factory Showcase: A Tale of Transformation in Collaboration with Andea and 3DS

CoorsTek Factory Showcase: A Tale of Transformation in Collaboration with Andea and 3DS We’re thrilled to invite you to one of the most anticipated events

Improve your laboratory efficiency and streamlining planning processes

Improve your laboratory efficiency and streamlining planning processes Digital transformation in life science happens continuously, quickly, and in front of our eyes. Changes are driven

Intelligent planning and scheduling for life science manufacturing excellence

Intelligent planning and scheduling for life science manufacturing excellence In today’s world, life science transformation is increasingly more important for environment and has a significant